The quality of our metalwork is the end result of modern construction technologies but is also clear to see in the details.

The eye bolts can be used to lift single cabinets, while banks of two or more cabinets are lifted using a lifting bracket. Both are fastened to the top of the M12 coupling.

The turn handle gives the cabinet an attractive, elegant design. The cylinder’s sliding cover can be customised with a logo of the customer’s choice.

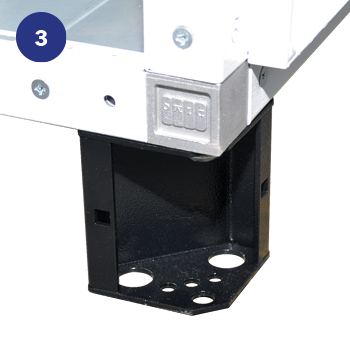

The rectangular plinth enables the cabinet to be mounted and fastened to the floor without lifting the cabinet or removing the base flange.

The 200 mm high reinforcement on the plinths allows the cabinet to be handled without compromising its stability.

The hinge allows the door to be disassembled without removing the axle pin, making the operation much easier and faster.

The metal locking system provides maximum robustness and the twist rods provide IP55 protection thanks to the 4 locking points.

Metal rod lock stops prevent breakage or wear that would prevent the door from closing properly.

The panels and the doors are fitted with an M6 copper-threaded bar for the earthing connection.

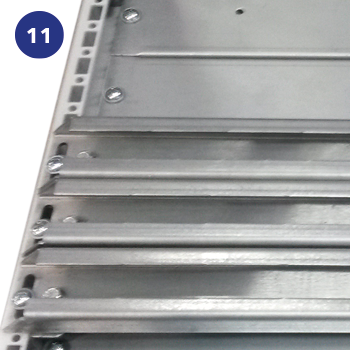

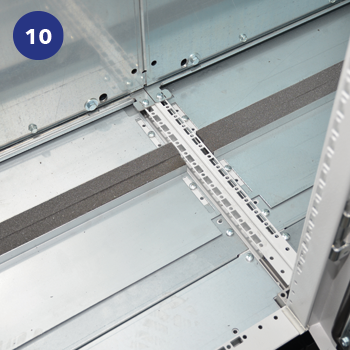

The upper and lower rail for the mounting plate is used for inserting from the front or the side.

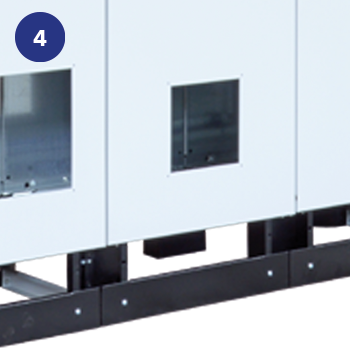

The modular base flanges enable all parts to be disassembled according to the set position for cable entry.

Metal rod lock

stops prevent breakage or wear that would prevent the door from closing properly.