An MCC cabinet with fixed drawers is a low-voltage switchboard containing a series of non-removable “drawers” or compartments. Each drawer is dedicated to the control and protection of a single utility, typically an electric motor.

Main features:

- Internal separation: drawers are physically separated from each other and from the main busbar system. This separation, in accordance with IEC EN 61439-2, ensures a high level of safety by limiting the propagation of any faults (such as an electric arc) to other parts of the switchboard.

- Dedicated componentsspace inside each drawer is designed to hold all the components required for starting, controlling and protecting the motor.

- Busbar system: a system of copper or aluminium bars, positioned vertically or horizontally within the cabinet, distributes the energy to the individual drawers.

- Cable compartment: a dedicated area, often to the side or rear, facilitates the entry and connection of power and control cables from the field.

180° door opening

Facilitated access

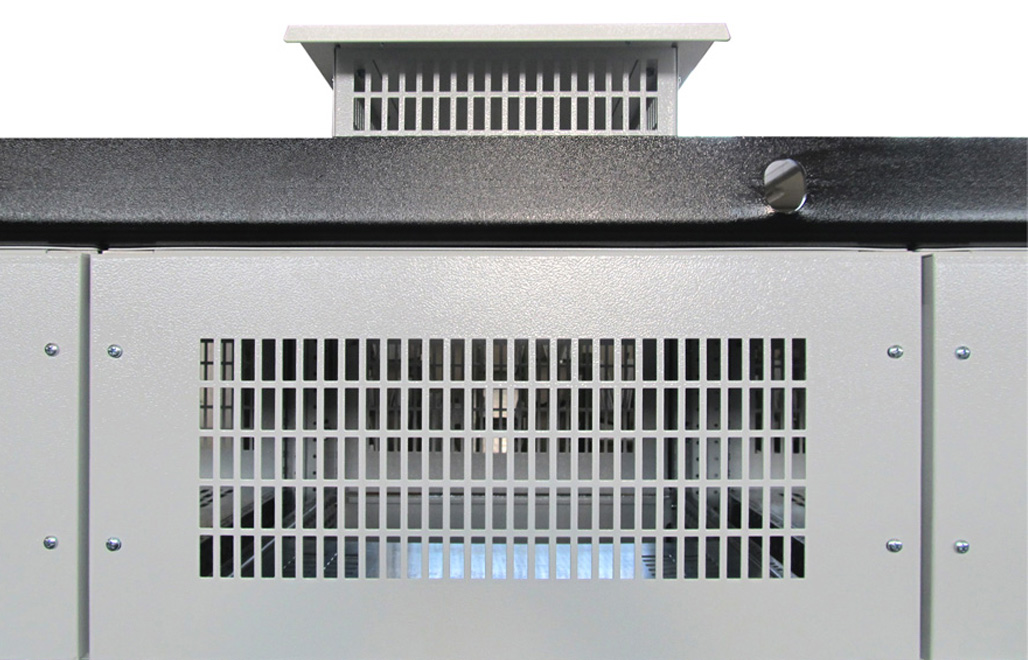

Internal ventilation system for each cubicle

Swivel handle customisable with customer logo

Technical details

A dedicated area, often to the side or rear, facilitates the entry and connection of power and control cables from the field

The separation of compartments ensures a high level of safety by limiting the propagation of any faults (such as an electric arc) to other parts of the switchboard, in accordance with IEC EN 61439-2

Possibility of providing a natural ventilation tower

A dedicated area, often lateral or posterior, facilitates the entry and connection of power and control cables coming from the field.

The interior of the compartments is designed to hold all the components required for starting, controlling and protecting the motor

Robust and reliable: the fixed structure and lower mechanical complexity make them extremely robust and less prone to faults arising from moving contacts or extraction mechanisms.

Simple wiring:installation and wiring can be simpler and more straightforward.

Less mechanical maintenance required: the absence of moving parts reduces the need for maintenance on connection mechanisms.

- Paper-making industry

- Iron metallurgy industry

- Manufacturing industry: for controlling motors in machinery, conveyor belts, pumps and fans.

- Water treatment:in drinking water and purification plants

- Food and beverage industry:in applications where scheduled downtimes are the norm

I prodotti Mazzieri per l’automazione industriale dispongono delle principali certificazioni e garantiscono la conformità alle normative di riferimento ed ai requisiti richiesti in ambito internazionale.

Involucri vuoti per apparecchiature assiemate di protezione e di manovra per B.T.

Degree of protection

IP55

Degree of protection

IK10 (solid door) IK08 (transparent door)

Short-circuit withstand strength test at Kema Laboratories Prague

Presence of polluting metals or materials according to Directive 2011/65/EU