The new pre-treatment plant, recently integrated into the company’s existing coating line, is not only a technical improvement but an additional guarantee on the final quality of our metalwork. An investment in the foundations in order to offer you even more corrosion-resistant and impeccably finished metalwork for switchboards and cabinets.

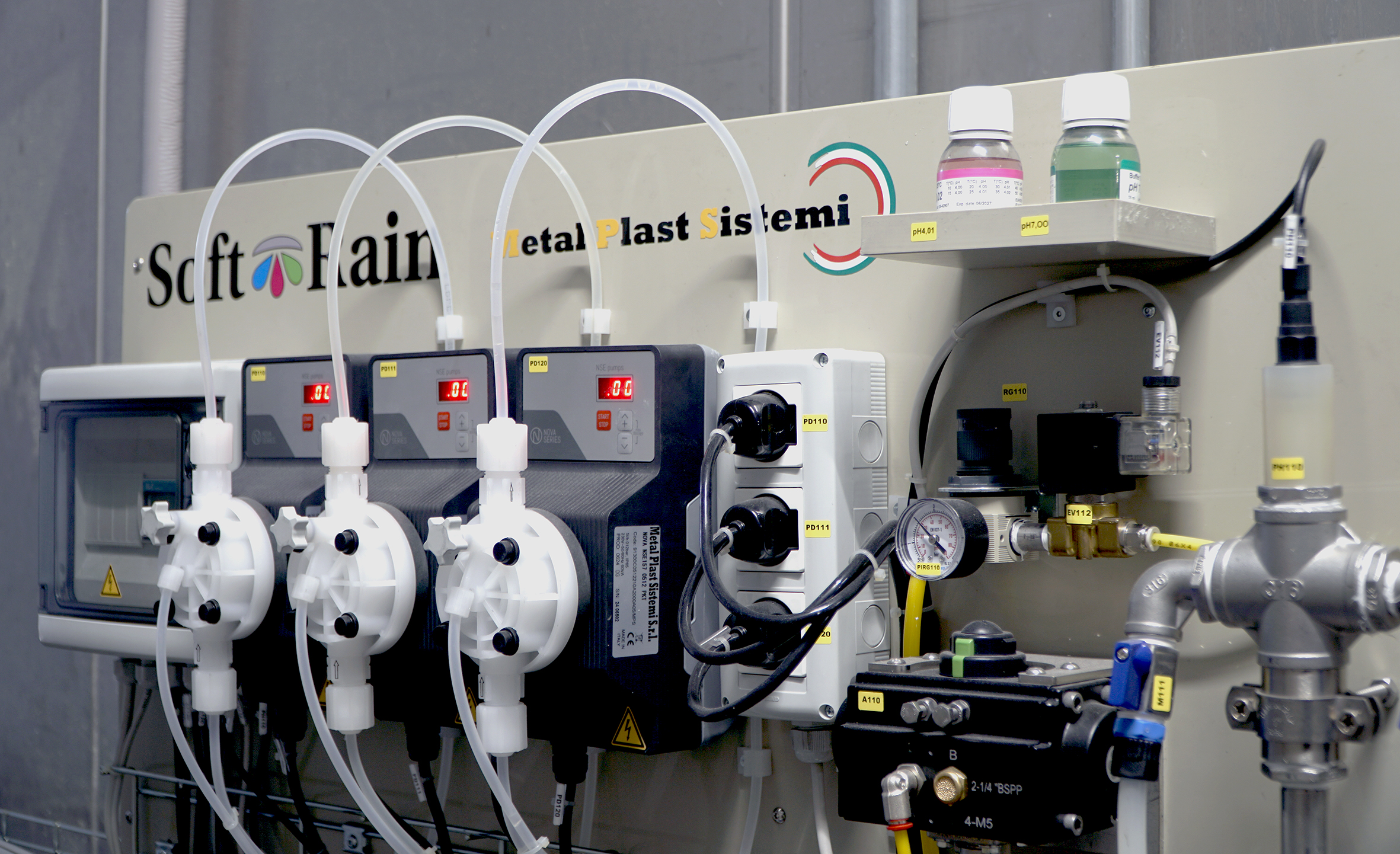

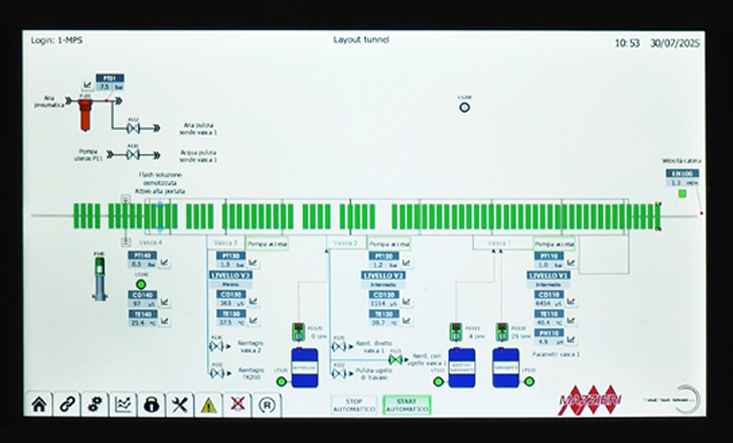

The new, technologically advanced plant allows us to achieve high quality standards because it guarantees optimal surface preparation before coating thanks to an advanced process of continuous control and monitoring of the pre-treatment phase, including:

The end result translates into real benefits for our metalwork: greater durability and wear resistance, spotlessly clean and flawless surfaces, greater protection against corrosion, impeccable finishes.